| |

| Home |

| About Us |

| Canvas Tarpaulin |

| Lightweight PE Tarpaulin |

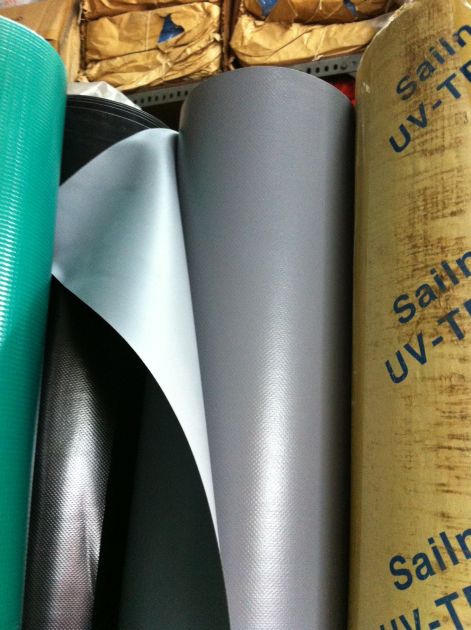

| PVC Coated Tarpaulin |

| Vinylon Tarpaulin |

| Cotton Canvas |

| Marine Supplies |

| Industrial Products |

| Contact Us |

| Fire-retardant Canvas Tarpaulin |

Fire takes a steady toll of both human life and property. The results are often tragic and in many cases (at least potentially) avoidable. The problem has many components which can be summarised as follows: 1. A wide range of commonly used textile materials is flammable. Use of reduced flammability textile materials, testing of both textile materials and complete products, regulations and legislation have been applied to the problem. Each has contributed to reducing the risk of accidental injury, death or loss. Progress in reducing the hazard has been made, but is constrained by a series of factors. 1. The risk is not widely appreciated by the general public, except when a major disaster occurs. 2. Any solution which restricts personal freedom is likely to be avoided by a significant number of people. 3. Any canvas tarpaulin products with reduced aesthetic qualities will be less successful even if it has fire-retardant properties. 4. Any solution which adds singnificantly to product cost will tend to be resisted. The terms "flameproof" and "fire-proof" should be avoided. "Fire-retardant" is a useful general term. "Do not sustain flame" is the approved term (BS6336: 1982). "Self-extinguishing" is widely used to describe canvas tarpaulin materials which only burn in contact with an ignition source. "Reduced fire hazard" or "resists ignition" are also acceptable terms but should only be used in connection with a specified test. Thermoplastic fibres as low flammability materials The cost of fire retardant The extra cost of textile materials with reduced fire hazard is also significant. In the upholstery field, back-coating finishes are available which give durable fire retardant action. They add about 10% - 20% to material cost. At the other end of the scale, specialist fire-retardant fibres can cost three to five times as much as equivalent general textile fibres. In barrier-layer applications, the choice of barrier fabric is between oxidised acrylic and fire-retardant treated cotton canvas. Oxidised acrylic has reduced fume generation, and cost up to four times the price of an equivalent cotton canvas fabric. Fire-retardant treated cotton canvas and wool costs 20%-50% more than equivalent untreated fabric. There is also some loss of aesthetic properties. In view of that, it is not perhaps not suprising that fire-retardant solutions tend to be confined to products that meet specific hazards. Good examples are children's nightwear, aircraft and train interiors, public auditoriums, and protective clothing. Please click on the following to return to canvas tarpaulin introduction |

Disclaimer : Privacy policy : Terms & conditions of use: Site map

Home : About Us : Canvas Tarpaulin : Lightweight PE Tarpaulin : PVC Coated Tarpaulin: Vinylon Tarpaulin : Cotton Canvas : Marine Supplies : Industrial Products : Contact Us